KNOTT basic systems for disc brakes

These systems are highly controllable, have constant coefficients and are not affected by either temperature or speed fading. This is also true where our disc brakes are concerned. Whether we select from our standard range or offer a custom solution, it will always meet your needs. Here is an overview:

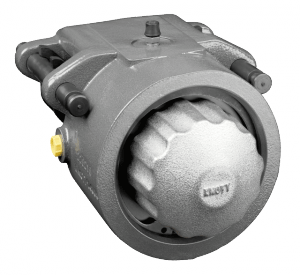

1. Spring pack sliding calliper brakes

These brakes work according to the “fail safe” principle, which means in a normal operating state of the vehicle, the brake is released by constant pressure supply. If there is a pressure drop safe braking is ensured by the spring pack.

Spring pack sliding calliper brakes are especially suitable as service and auxiliary brakes mounted on gearbox output flanges and final drive flanges. The encapsulated design is ideal for off-road applications.

Available sizes: diameter 75 – 110 mm

Braking torques: up to 9.500 Nm

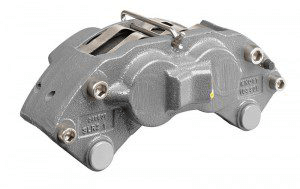

2. Hydraulic fixed-calliper disc brakes

These brakes are characterised by a fixed connection with the wheel suspension. The braking force on the brake disc is produced by two pistons mounted in opposition.

The advantage: in contrast to floating or sliding callipers, fixed-calliper disc brakes have no sliding elements and can be used off-road or in dirty environments.

Available sizes: 2, 4 or 6 pistons with diameter of 40 – 92 mm

Braking torques: up to 120,000 Nm

3. Hydraulic sliding calliper disc brakes

The application of the operating force in hydraulic sliding calliper disc brakes takes place via one or more pistons. The operating force of the opposite side is produced by the reaction force of the sliding calliper, which is supported by the brake pads on the disc.

This design makes it possible for the brakes to be mounted as usual in the wheel rim. Generally, this brake design is suitable for on-road applications where restricted installation space is the case. Typical applications are for municipal vehicles, airport equipment and trailers etc.

Available sizes: 1 or 2 pistons with diameter of 40 – 72 mm

Braking torques: up to 10,000 Nm

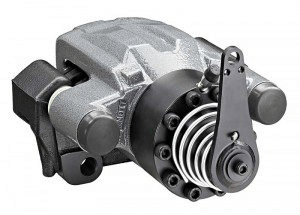

4. Mechanical sliding calliper disc brakes

These brakes employ a brake lever that is controlled by compressed air, a hydraulic or spring pack cylinder, or via a control cable or linkage and a hand-brake lever. Mechanical sliding callipers are used as service and auxiliary brakes.

Available sizes: MGS 22, MGS 33, MGS 40, MGS 45 and MZB 40

Braking torques: up to 6000 Nm

5. Pneumatic disc brakes

The operation of a pneumatic disc brake takes place on one side only via an external diaphragm cylinder. The operating force of the opposite side is produced via the reaction force of the sliding calliper. The advantages over conventional systems are compact design, ease of service, and stable braking performance.

Applications for pneumatic disc brakes are found in heavy commercial on-road vehicles such as lorries, busses, mobile cranes as well as in trailers.

Available sizes: PGS 15 and PGS 22

Braking torques: up to 25,000 Nm

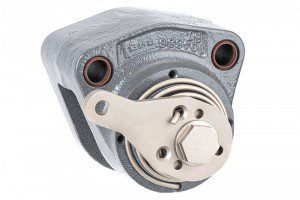

6. Hydromechanical sliding calliper brakes

These brakes offer not only a service brake function but also an integrated parking brake function. The application of operating forces is from one side only, either hydraulically via the service brake piston or mechanically via the brake levers. The operating force on the other side is produced via the reaction force of the sliding calliper itself.

One important advantage of our bakes is the reinforced components of the parking brake unit, which allow the vehicle to be stopped on steep gradients. The brakes are mainly used in construction machinery and special vehicles.

Available sizes: piston diameter 52 – 56 mm

Braking torques: up to 2600 Nm